Greene Township near Fayetteville in Franklin County, Pennsylvania — The American Northeast (Mid-Atlantic)

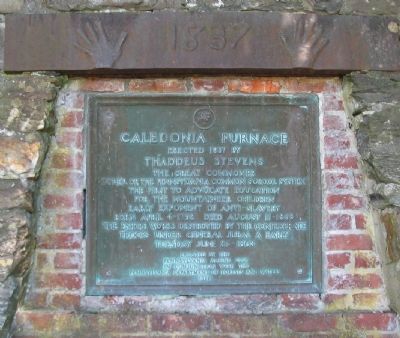

Caledonia Furnace

Thaddeus Stevens

the great commoner

father of the Pennsylvania common school system

the first to advocate education

for the mountaineer children

early exponent of anti-slavery

born April 4, 1792 died August 11, 1868

the entire works destroyed by the Confederate

troops under General Jubal A Early

Tuesday June 26, 1863

erected by the

Pennsylvania Alpine Club

in conjunction with the

Pennsylvania Department of Forests and Waters

1927

Erected 1927 by Pennsylvania Alpine Club.

Topics. This historical marker is listed in these topic lists: Industry & Commerce • War, US Civil. A significant historical month for this entry is April 1860.

Location. 39° 54.415′ N, 77° 28.675′ W. Marker is near Fayetteville, Pennsylvania, in Franklin County. It is in Greene Township. Marker is at the intersection of Lincoln Highway (U.S. 30) and State Route 233, on the right when traveling west on Lincoln Highway. Affixed to a reconstruction of the furnace. Touch for map. Marker is at or near this postal address: 30 Pine Grove Rd, Fayetteville PA 17222, United States of America. Touch for directions.

Other nearby markers. At least 8 other markers are within 5 miles of this marker, measured as the crow flies. The Good Roads Jubilee / The Lincoln Highway (a few steps from this marker); Basic Ingredients (within shouting distance of this marker); Making Iron (within shouting distance of this marker); The Workers Pyramid (within shouting distance of this marker); a different marker also named Caledonia Furnace (within shouting distance of this marker); Thaddeus Stevens Blacksmith Shop (within shouting distance of this marker); Mary Jemison (approx. 2.8 miles away); a different marker also named Mary Jemison (approx. 4.4 miles away). Touch for a list and map of all markers in Fayetteville.

Also see . . . Caledonia Furnace. Discussion of the furnace's construction and history. Includes an undated photo of the original. (Submitted on September 22, 2008, by Craig Swain of Leesburg, Virginia.)

Photographed By William Fischer, Jr., November 29, 2008

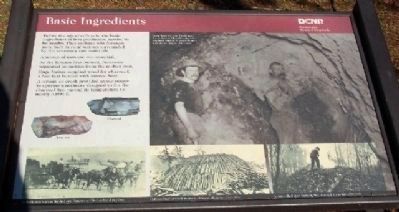

5. Basic Ingredients

Interpretive marker in front of the furnace reconstruction:

Before the age of railroads the basic ingredients of iron production needed to be nearby. That explains why furnaces were built in rural settings surrounded by the necessary raw materials.

A source of iron ore was essential.

As the furnace fires burned, limestone separated impurities from the molten iron.

Huge forests supplied wood for charcoal, a fuel that burned with intense heat.

A stream or creek provided water power to operate machinery designed to fan the charcoal fire, raising its temperature to nearly 3,000 F.

Before the age of railroads the basic ingredients of iron production needed to be nearby. That explains why furnaces were built in rural settings surrounded by the necessary raw materials.

A source of iron ore was essential.

As the furnace fires burned, limestone separated impurities from the molten iron.

Huge forests supplied wood for charcoal, a fuel that burned with intense heat.

A stream or creek provided water power to operate machinery designed to fan the charcoal fire, raising its temperature to nearly 3,000 F.

Photographed By William Fischer, Jr., November 29, 2008

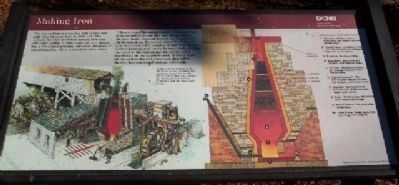

6. Making Iron

Interpretive marker in front of furnace reconstruction:

The ironmaking process was well-known and cold-blast furnaces built in 18th and 19th century America mimicked designs first used 400 years earlier. A thick stone furnace, shaped like a flat-topped pyramid, served as the place of transformation, where minerals became metal. Fillers dumped alternating layers of charcoal fuel, iron ore, and limestone flux into the top of the furnace. As the charcoal burned, air forced into the furnace from the outside raised the temperature to 2,600-3,000 F creating several byproducts. Carbon gases escaped up the furnace stack, molten iron slag floated on the liquified metal. Workers drew off the useless slag and guttermen channelled the iron into connected castings called pigs.

Cutaway drawings depict the working of the furnace.

The ironmaking process was well-known and cold-blast furnaces built in 18th and 19th century America mimicked designs first used 400 years earlier. A thick stone furnace, shaped like a flat-topped pyramid, served as the place of transformation, where minerals became metal. Fillers dumped alternating layers of charcoal fuel, iron ore, and limestone flux into the top of the furnace. As the charcoal burned, air forced into the furnace from the outside raised the temperature to 2,600-3,000 F creating several byproducts. Carbon gases escaped up the furnace stack, molten iron slag floated on the liquified metal. Workers drew off the useless slag and guttermen channelled the iron into connected castings called pigs.

Cutaway drawings depict the working of the furnace.

Photographed By William Fischer, Jr., November 29, 2008

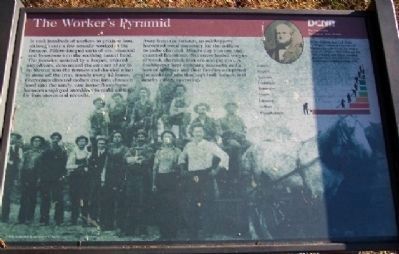

7. The Worker's Pyramid

Interpretive marker in front of the reconstructed furnace:

It took hundreds of workers to produce iron although only a few actually worked at the furnace. Fillers dumped carts of ore, charcoal and limestone into the seething tunnel head. The founder, assisted by a keeper, ordered ingredients, determined the amount of air to be blasted into the furnace and decided when to draw off the iron, usually every 12 hours. Guttermen directed molten iron into channels hoed into the sandy, cast house floor. Some furnaces employed moulders to make castings for iron stoves and utensils.

Away from the furnace, woodchoppers harvested wood necessary for the colliers to make charcoal. Miners dug iron ore and quarried limestone. Teamsters hauled wagons of wood, charcoal, iron ore, and pig iron. A bookkeeper kept company accounts, and a host of laborers and their families completed the unskilled jobs that kept both furnace and nearby village operating.

It took hundreds of workers to produce iron although only a few actually worked at the furnace. Fillers dumped carts of ore, charcoal and limestone into the seething tunnel head. The founder, assisted by a keeper, ordered ingredients, determined the amount of air to be blasted into the furnace and decided when to draw off the iron, usually every 12 hours. Guttermen directed molten iron into channels hoed into the sandy, cast house floor. Some furnaces employed moulders to make castings for iron stoves and utensils.

Away from the furnace, woodchoppers harvested wood necessary for the colliers to make charcoal. Miners dug iron ore and quarried limestone. Teamsters hauled wagons of wood, charcoal, iron ore, and pig iron. A bookkeeper kept company accounts, and a host of laborers and their families completed the unskilled jobs that kept both furnace and nearby village operating.

Credits. This page was last revised on February 7, 2023. It was originally submitted on September 22, 2008, by Craig Swain of Leesburg, Virginia. This page has been viewed 1,426 times since then and 61 times this year. Photos: 1. submitted on September 22, 2008, by Craig Swain of Leesburg, Virginia. 2. submitted on September 20, 2008, by Craig Swain of Leesburg, Virginia. 3, 4. submitted on September 22, 2008, by Craig Swain of Leesburg, Virginia. 5, 6, 7. submitted on December 3, 2008, by William Fischer, Jr. of Scranton, Pennsylvania.