Birmingham in Jefferson County, Alabama — The American South (East South Central)

Slag

Sloss Furnaces National Historic Landmark

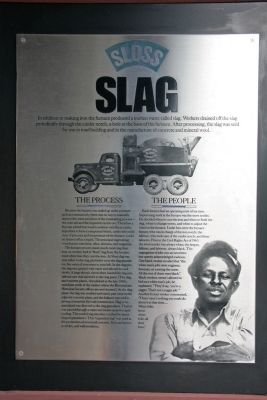

In addition to making iron the furnace produced a molten waste called slag. Workers drained off the slag periodically through the cinder notch, a hole at the base of the furnace. After processing, the slag was sold for use in road building and in the manufacture of concrete and mineral wool.

The Process

Because the furnace was sealed up under pressure and ran continuously, there was no way to manually remove the waste products of the ironmaking process—the coke ash and the impurities in the ore. Therefore a flux was added that would combine with these earthy impurities to form a compound which, under the conditions of pressure and temperature of the furnace, could be drained off as a liquid. The principal slagmaking constituents were lime, silica, alumina, and magnesia.

The furnace process made much more slag than iron, so workers had to "flush" slag from the furnace more often than they cast the iron. At Sloss slag was sent either to the slag pits below or to the slag granulator, the series of structures to your left. In the slag pits, the slag was sprayed with water and allowed to cool slowly. A large electric shovel then loaded the slag into railroad cars that carried it to the slag plant. (The slag and concrete plants, demolished in the late 1960s, stood just north of the viaduct where the Birmingham Historical Society offices are now located.) At the slag plant, the slag was crushed and sized; part went to the adjacent concrete plant, and the balance was sold to paving contractors for road construction. Slag to be granulated was directed to the slag granulator. There it was passed through a water and steam spray for rapid cooling. The cooled slag was then crushed by drum-shaped granulators. This "expanded slag" was used in the production of structural concrete, floor and acoustical tiles, and wall insulation.

The People

Each furnace had an operating crew of six men. Supervising work at the furnace was the stove tender. He decided when to cast the iron and when to flush the slag, when to change stoves, and when to adjust the wind on the furnace. Under him were the furnace keeper, who was in charge of the iron notch; the fallman, who took care of the cinder notch; and three laborers. Prior to the Civil Rights Act of 1965 the stove tender was always white; the keeper, fallman, and laborers, always black. This segregation of jobs was an unwritten but openly acknowledged tradition. One black worker recalled that "the white man's jobs were engineer, foreman, or running the crane. All the rest of them were black." Black workers weren't allowed to bid on a white man's job, he explained, "They'd say, 'you're a nigger. That's not a nigger

job.'"

Another former worker commented, "There wasn't nothing you could do about it at that time... White folks been white folks all their lives."

Erected by Sloss Furnaces National Historic Landmark.

Topics. This historical marker is listed in this topic list: Industry & Commerce. A significant historical year for this entry is 1965.

Location. 33° 31.241′ N, 86° 47.463′ W. Marker is in Birmingham, Alabama, in Jefferson County. Marker can be reached from the intersection of 32nd Street North and 2nd Avenue North, on the left when traveling north. This marker is located on the grounds of the Sloss Furnaces National Historic Landmark. Touch for map. Marker is at or near this postal address: 20 32nd Street North, Birmingham AL 35222, United States of America. Touch for directions.

Other nearby markers. At least 8 other markers are within walking distance of this marker. The Gas System (a few steps from this marker); The Blast Furnace (a few steps from this marker); Casting Pigs (within shouting distance of this marker); The Stock Trestle (within shouting distance of this marker); Ironmaking (within shouting distance of this marker); Stock Trestle/Tunnel (within shouting distance of this marker); Boilers (within shouting distance of this marker); Sloss Quarters (within shouting distance of this marker). Touch for a list and map of all markers in Birmingham.

Also see . . . Sloss Furnaces National Historic Landmark. (Submitted on October 7, 2013.)

Credits. This page was last revised on July 8, 2021. It was originally submitted on October 6, 2013, by Timothy Carr of Birmingham, Alabama. This page has been viewed 691 times since then and 28 times this year. Last updated on May 29, 2015, by J. Makali Bruton of Accra, Ghana. Photos: 1, 2. submitted on October 6, 2013, by Timothy Carr of Birmingham, Alabama. 3. submitted on October 8, 2013. • Bill Pfingsten was the editor who published this page.