Near Copake Falls in Columbia County, New York — The American Northeast (Mid-Atlantic)

Charcoal Blast Furnace Operations

Iron Works Trail

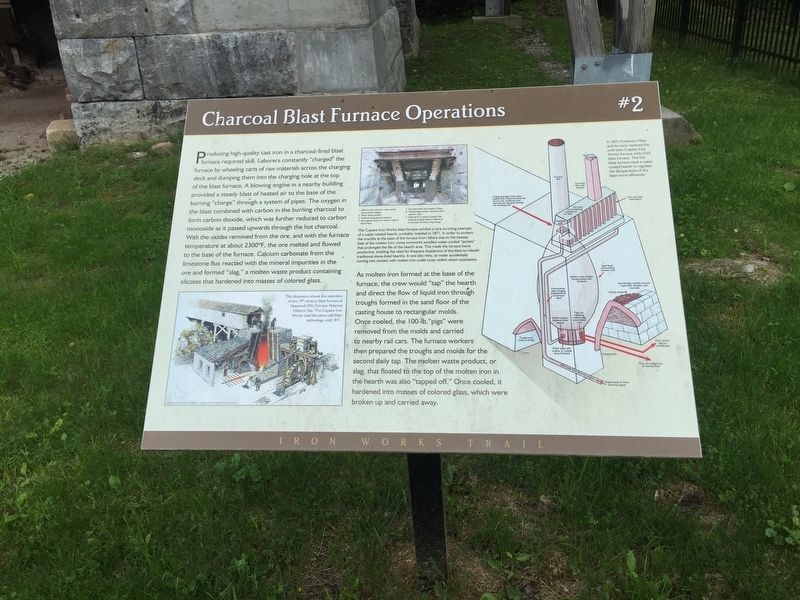

Producing high-quality cast iron in a charcoal-fired blast furnace required skill. Laborers constantly “charged” the furnace by wheeling carts of raw materials across the charging deck and dumping them into the charging hole at the top of the blast furnace. A blowing engine in a nearby building provided a steady blast of heated air to the base of the burning “charge” through a system of pipes. The oxygen in the blast combined with carbon in the burning charcoal to form carbon dioxide, which was further reduced to carbon monoxide as it passed upwards through the hot charcoal. With the oxides removed from the ore, and with the furnace temperatures about 2300 F, the ore melted and flowed to the base of the furnace. Calcium carbonate from the limestone reacted with the mineral impurities in the ore and formed “Slag”, a molten waste product containing silicates that hardened into masses of colored glass.

As molten iron formed at the base of the furnace, the crew would “tap” the hearth and direct the flow of liquid iron through troughs formed in the sand floor of the casting house to rectangular molds. Once cooled, the 100-lb. “pigs” were removed from the molds and carried to nearby rail cars. The furnace workers then prepared the troughs and molds for the second daily tap. The molten waste product, or slag, that floated to the top of the molten iron in the hearth was also “tapped off.” Once cooled, it hardened into masses of colored glass, which were broken up and carried away.

Top Inset: The Copake Iron Works blast furnace exhibits a rare surviving example of a water=cooled hearth, probably installed in 1871. In order to protect the crucible at the base of the furnace from failure due to the intense heat of the molten iron, some ironworks installed water-cooled “jackets” that prolonged the life of the hearth area. This made the furnace more productive, avoiding the need for frequent shutdowns of the blast to rebuild traditional stone-lined hearths. It was also risky, as water accidentally coming into contact with molten iron could cause a violent steam explosion.

Bottom Illustration: The illustration shows the operation of the 19th century blast furnace at Hopewell (PA) Furnace National Historic Site. The Copake Iron Works used the same cold blast technology until 1871. (Marker Number 2.)

Topics. This historical marker is listed in this topic list: Industry & Commerce. A significant historical year for this entry is 1871.

Location. 42° 7.146′ N, 73° 30.848′ W. Marker is near Copake Falls, New York, in Columbia County. Marker can be reached from Valley View Road. Blast furnace is located in Taconic State Park. Touch for map. Marker is in this post office area: Copake Falls NY 12517, United States of America. Touch for directions.

Other nearby markers. At least 8 other markers are within walking distance of this marker. Copake Iron Works (here, next to this marker); Blowing Engine House (within shouting distance of this marker); Pomeroy (within shouting distance of this marker); Pomeroy Homes (about 400 feet away, measured in a direct line); a different marker also named Copake Iron Works (about 400 feet away); Site of Pomeroy Houses (about 500 feet away); Isaac Chesbrough House (about 500 feet away); Blast Furnace & Charging Deck (about 500 feet away). Touch for a list and map of all markers in Copake Falls.

Regarding Charcoal Blast Furnace Operations. The description of the chemistry is a little confusing on the marker. The actual reducing agent converting iron ore (essentially iron oxides or rust) to elemental iron is carbon monoxide. Burning carbon (charcoal or coke) produces carbon dioxide. Carbon and carbon dioxide are in equilibrium with carbon monoxide that becomes more favorable for the formation of carbon monoxide with rising temperature.

Also see . . . Copake Iron Works Historic District - National Archives. National Register of Historic Places documentation (Submitted on January 17, 2024, by Anton Schwarzmueller of Wilson, New York.)

Credits. This page was last revised on January 17, 2024. It was originally submitted on June 26, 2019, by Steve Stoessel of Niskayuna, New York. This page has been viewed 266 times since then and 30 times this year. Photos: 1, 2, 3, 4. submitted on June 26, 2019, by Steve Stoessel of Niskayuna, New York. • Bill Pfingsten was the editor who published this page.