Thurmont in Frederick County, Maryland — The American Northeast (Mid-Atlantic)

"Isabella" and Casting Shed

Catoctin Iron Furnace

A Village and Its Resources:

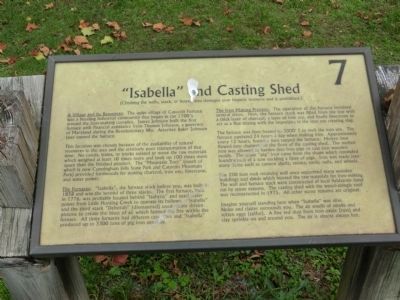

The quiet village of Catoctin Furnace was a bustling industrial community that began in the 1700’s around the Iron-making complex James Johnson built the first furnace with financial assistance from Thomas Johnson, a governor of Maryland during the Revolutionary War. Attorney Baker Johnson later owned the furnace. This location was chosen because of the availability of natural resources in the area and the relatively poor transportation of that time. No canals, trains or trucks existed to move the raw materials which weighed at least 10 times more and took up 100 times more space than the finished product. The “Mountain Tract” (much of which is now Cunningham Falls State Park and Catoctin Mountain Park) provided hardwoods for making charcoal, iron ore, limestone, and water power.

The Furnaces:

“Isabella”, the furnace stack before you, was built in 1858 and was the second of three stacks. The first furnace, built in 1776, was probably located behind “Isabella” and used water power from Little Hunting Creek to operate its bellows. “Isabella” and the third stack “Deborah” (dismantled) used steam driven pistons to create the blast of air which fanned the fire within the furnace. All three furnaces had different capacities and “Isabella” produced up to 3300 tons of pig iron annually.

The Iron Making Process:

The operation of the furnace involved several steps. First, the furnace stack was filled from the top with a thick layer of charcoal, a layer of iron ore, and finally limestone to act as a flux mixing with the impurities in the iron ore creating slag.

The furnace was then heated to 3000 degrees F to melt the iron ore. The furnace operated 24 hours a day when making iron. Approximately every 12 hours, foundry men tapped the furnace. Molten iron flowed into channels on the floor of the casting shed. The molten iron was allowed to harden into iron pigs or cast into wooden molds. The name “pig” iron came from the shape which reminded foundry men of a sow suckling a litter of pigs. Iron was made into many items such as cannon shells, stoves, tools nails, and wheels.

The 200 foot rock retaining wall once supported many wooden building and sheds which housed the raw materials for iron-making. The wall and furnace stack were constructed of local fieldstone hand cut by stone masons. The casting shed with the wood-shingle roof was reconstructed in 1975. All other stone remains are original.

Imagine yourself standing here when “Isabella” as alive. Noise and clatter surrounds you. The air smells of smoke and rotten eggs (sulfur). A fine red dust from iron oxide (rust) and clay sprinkle on and around you. The air is almost always hot.

Topics. This historical marker is listed in this topic list: Industry & Commerce. A significant historical year for this entry is 1858.

Location. Marker has been reported missing. It was located near 39° 34.428′ N, 77° 25.878′ W. Marker was in Thurmont, Maryland, in Frederick County. Marker was on Blacks Mill Road. Touch for map. Marker was in this post office area: Thurmont MD 21788, United States of America. Touch for directions.

Other nearby markers. At least 8 other markers are within walking distance of this location. Erasure and Rediscovery (approx. 0.4 miles away); The Return of Names (approx. 0.4 miles away); An Unquiet Place (approx. 0.4 miles away); Dynamic Nature of History (approx. 0.4 miles away); Who Built this Village? (approx. 0.4 miles away); Secondary Industries and the Mill Pond (approx. 0.4 miles away); Harriet Chapel (approx. 0.4 miles away); Resources: Use—Reuse—Recycle (approx. half a mile away). Touch for a list and map of all markers in Thurmont.

Credits. This page was last revised on October 22, 2021. It was originally submitted on November 21, 2012, by Don Morfe of Baltimore, Maryland. This page has been viewed 674 times since then and 15 times this year. Last updated on October 22, 2021, by Allen C. Browne of Silver Spring, Maryland. Photos: 1, 2, 3, 4, 5. submitted on November 21, 2012, by Don Morfe of Baltimore, Maryland. 6. submitted on October 22, 2021, by Allen C. Browne of Silver Spring, Maryland. • J. Makali Bruton was the editor who published this page.