Tahawus in Essex County, New York — The American Northeast (Mid-Atlantic)

“New” McIntyre Furnace

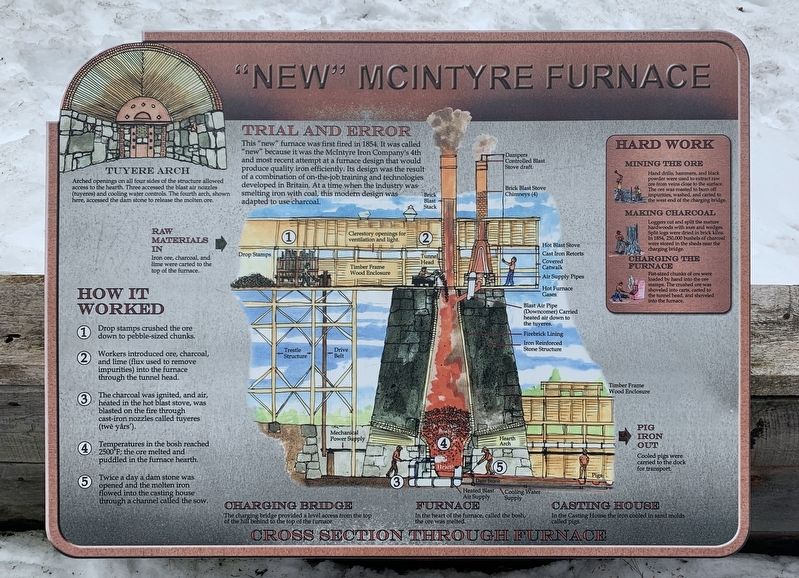

Cross Section Through Furnace

TRIAL AND ERROR

This "new” furnace was first fired in 1854. It was called "new” because it was the McIntyre Iron Company's 4th and most recent attempt at a furnace design that would produce quality iron efficiently. Its design was the result of a combination of on-the-job training and technologies developed in Britain. At a time when the industry was smelting iron with coal, this modern design was adapted to use charcoal.

Sections of the Furnace (left to right)

CHARGING BRIDGE - The charging bridge provided a level access from the top of the hill behind to the top of the furnace.

FURNACE - In the heart of the furnace, called the bosh, the ore was melted.

CASTING HOUSE - In the Casting House the iron cooled in sand molds called pigs.

HOW IT WORKED

1. Drop stamps crushed the ore down to pebble-sized chunks.

2. Workers introduced ore, charcoal, and lime (flux used to remove impurities) into the furnace through the tunnel head.

3. The charcoal was ignited, and air, heated in the hot blast stove, was blasted on the fire through cast-iron nozzles called tuyeres (twe yârs').

4. Temperatures in the bosh reached 2500°F; the ore melted and puddled in the furnace hearth.

5. Twice a day a dam stone was opened and the molten iron flowed into the casting house through a channel called the sow.

Right Inset

Hard Work

MINING THE ORE

Hand drills, hammers, and black powder were used to extract raw ore from veins close to the surface. The ore was roasted to burn off impurities, washed, and carted to the west end of the charging bridge.

MAKING CHARCOAL

Loggers cut and split the mature hardwoods with axes and wedges. Split logs were dried in brick kilns. In 1854, 250,000 bushels of charcoal were stored in the sheds near the charging bridge.

CHARGING THE FURNACE

Fist-sized chunks of ore were loaded by hand into the ore stamps. The crushed ore was shoveled into carts, carted to the tunnel head, and shoveled into the furnace.

Upper Left Inset

TUYERE ARCH

Arched openings on all four sides of the structure allowed access to the hearth. Three accessed the blast air nozzles (tuyeres) and cooling water controls. The fourth arch, shown here, accessed the dam stone to release the molten ore.

Erected by Open Space Institute.

Topics. This historical marker is listed in this topic list: Industry & Commerce. A significant historical year for this entry is 1854.

Location. 44° 4.727′ N, 74° 3.375′ W. Marker is in Tahawus, New York, in Essex County. Marker can be reached from Upper Works Road (Route 25) 9.1 miles north of Blue Ridge Road, on the right when traveling north. Marker can be reached by the trail from the parking area. Marker is at the eastern base of the furnace. Touch for map. Marker is in this post office area: Newcomb NY 12879, United States of America. Touch for directions.

Other nearby markers. At least 8 other markers are within walking distance of this marker. Making Bricks (a few steps from this marker); An Iron Making Complex (a few steps from this marker); A Monumental Structure (a few steps from this marker); Hudson Powered (within shouting distance of this marker); Heavy Construction (within shouting distance of this marker); Tahawus Clubhouse (approx. half a mile away); Adirondac (approx. half a mile away); MacNaughton Cottage (approx. 0.6 miles away). Touch for a list and map of all markers in Tahawus.

More about this marker.

Raw Materials - charcoal, Iron ore, lime -were carted to the top of the furnace (left)

After ignition, the temperature of furnace was raised by a blast of air from the Blast Air Pipe

(Downcomer) which carried heated air down to the tuyeres. (upper right of furnace)

After the furnace was tapped, the cooled pigs were carried to the dock for transport. (bottom right)

Also see . . .

1. Blast Furnace. (Submitted on April 3, 2020, by Steve Stoessel of Niskayuna, New York.)

2. Open Space Institute. (Submitted on April 6, 2020, by Michael Herrick of Southbury, Connecticut.)

Additional keywords. Engineering

Credits. This page was last revised on April 6, 2020. It was originally submitted on April 3, 2020, by Steve Stoessel of Niskayuna, New York. This page has been viewed 185 times since then and 18 times this year. Photo 1. submitted on April 3, 2020, by Steve Stoessel of Niskayuna, New York. • Michael Herrick was the editor who published this page.

Editor’s want-list for this marker. A wide angle photo of the marker and its surroundings. • Can you help?