Near Red Mountain in Kern County, California — The American West (Pacific Coastal)

The Baltic Mine Project

Topics. This historical marker is listed in this topic list: Natural Resources. A significant historical month for this entry is July 1993.

Location. Marker has been reported permanently removed. It was located near 35° 21.051′ N, 117° 37.904′ W. Marker was near Red Mountain, California, in Kern County. Marker was on Red Mountain Road, 0.8 miles west of U.S. 395, on the left when traveling west. Located at the end of an un-marked dirt road, at the top of a hill. Touch for map. Marker was in this post office area: Randsburg CA 93554, United States of America.

We have been informed that this sign or monument is no longer there and will not be replaced. This page is an archival view of what was.

Other nearby markers. At least 8 other markers are within 2 miles of this location, measured as the crow flies. The Kelly Silver Mine (here, next to this marker); The Baltic Mine (here, next to this marker); Yellow Aster Gold Mine (a few steps from this marker); a different marker also named Kelly Silver Mine (approx. 0.7 miles away); The Owl Hotel (approx. 0.7 miles away); Silver Dollar Saloon (approx. 0.8 miles away); The King Solomon Mine (approx. 1.2 miles away); Rand District Community Cemetery (approx. 1.3 miles away). Touch for a list and map of all markers in Red Mountain.

Additional commentary.

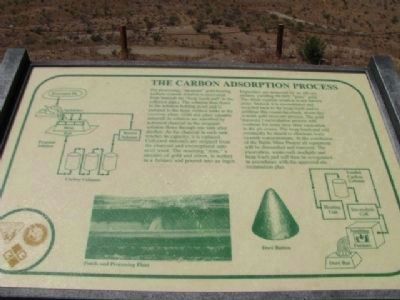

1. The Carbon Adsorption Process - See Photo #5

For processing, “pregnant” gold bearing sodium cyanide solution is recovered from beneath the “heap leach pad” in the collector pipes. The solution then flows to the solution holding pond and is pumped to the large vertical tanks at the recovery plant. Gold and other valuable minerals in solution are adsorbed by activated charcoal as the pregnant solution flows through one tank after another. As the charcoal in each tank reaches its capacity, it is replaced. Collected minerals are stripped from the charcoal and electroplated onto steel wool. The resulting “dore”, a mixture of gold and silver, is melted in a furnace and poured into an ingot. Impurities are removed by an off-site refiner, yielding 99.99% “pure” gold. The dilute cyanide solution is not thrown away. Instead, it is reconstituted and recycled back to the heap leach pad to continue this round the clock, seven day a week gold recovery process. The gold recovery/recirculation process will continue for some time after excavation in the pit ceases. The heap leach pad will eventually be rinsed to eliminate toxic cyanide concentrations. At the conclusion of the Baltic Mine Project all equipment will be dismantled and removed. The excavation, waste rock stockpile and heap leach pad will then be revegetated in accordance with the approval site reclamation plan.

— Submitted April 4, 2012, by Denise Boose of Tehachapi, California.

Credits. This page was last revised on July 19, 2020. It was originally submitted on March 24, 2012, by Denise Boose of Tehachapi, California. This page has been viewed 869 times since then and 66 times this year. Last updated on July 18, 2020, by Craig Baker of Sylmar, California. Photos: 1, 2, 3, 4, 5. submitted on March 24, 2012, by Denise Boose of Tehachapi, California. 6. submitted on July 18, 2020, by Craig Baker of Sylmar, California. • J. Makali Bruton was the editor who published this page.