Davis in Tucker County, West Virginia — The American South (Appalachia)

Inside The Sawmill

The Process of Making Lumber and Pulpwood from Felled Trees

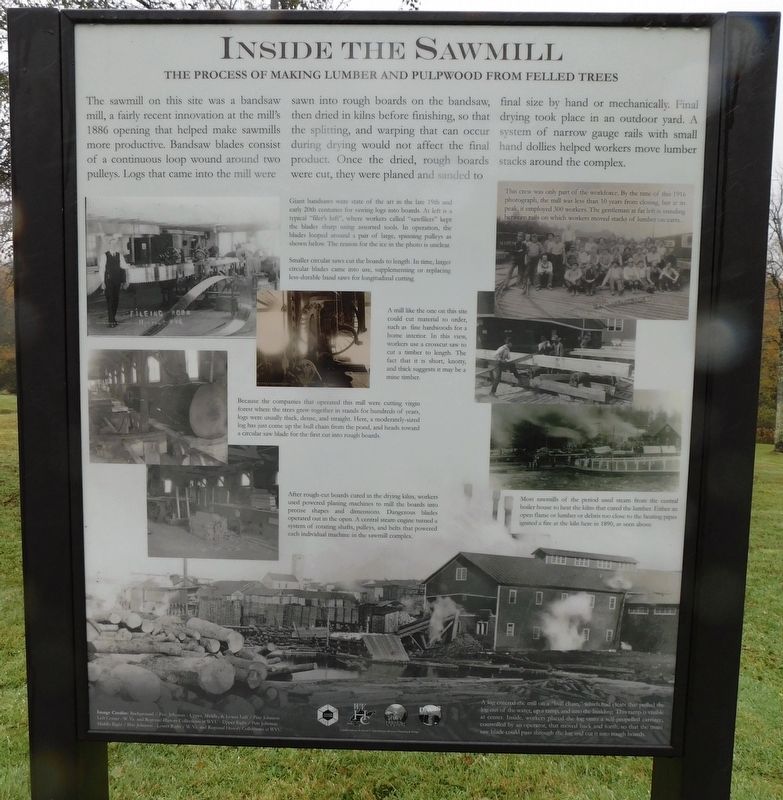

The sawmill on this site was a bandsaw mill, a fairly recent innovation at the mill's 1886 opening that helped make sawmills more productive. Bandsaw blades consist of a continuous loop wound around two pulleys. Logs that came into the mill were sawn into rough boards on the bandsaw, then dried in kilns before finishing, so that the splitting, and warping that can occur during drying would not affect the final product. Once the dried, rough boards were cut, they were planed and sanded to final size by hand or mechanically. Final drying took place in an outdoor yard. A system of narrow gauge rails with small hand dollies helped workers move lumber stacks around the complex.

(Captions):

Giant bandsaws were state of the art in the late 19th and early 20th centuries for sawing logs into boards. At left is a typical "filer's loft", where workers called "sawfilers" kept the blades sharp using assorted tools. In operation, the blades looped around a pair of large, spinning pulleys as shown below. The reason for the ice in the photo is unclear.

Smaller circular saws cut the boards to length. In time, larger circular blades came into use, supplementing or replacing less-durable band saws for longitudinal cutting.

A mill like the one on this site could cut material to order, such as fine hardwoods for a home interior. In this view, workers use a crosscut saw to cut a timber to length. The fact that it is short, knotty, and thick suggests it may be a mine timber.

Because the companies that operated this mill were cutting virgin forest where the trees grew together in stands for hundreds of years, logs were usually thick, dense, and straight. Here, a moderately-sized log has just come up the bull chain from the pond, and heads toward a circular saw blade for the first cut into rough boards.

After rough-cut boards cured in the drying kilns, workers used powered planing machines to mill the boards into precise shapes and dimensions. Dangerous blades operated out in the open. A central steam engine turned a system of rotating shafts, pulleys, and belts that powered each individual machine in the sawmill complex.

This crew was only part of the workforce. By the time of this 1916 photograph, the mill was less than 10 years from closing, but at its peak, it employed 300 workers. The gentleman at far left is standing between rails on which workers moved stacks of lumber on carts.

Most sawmills of the period used steam from the central boiler house to heat the kilns that cured the lumber. Either an open flame or lumber or debris too close to the heating pipes ignited a fire at the kiln here in 1890, as seen above.

A

log entered the mill on a "bull chain," which had cleats that pulled the log out of the water, up a ramp, and into the building. This ramp is visible at center. Inside, workers placed the log onto a self-propelled carriage, controlled by an operator, that moved back and forth, so that the main saw blade could pass through the log and cut it into rough boards.

Image Credits: Background / Pete Johnson - Upper, Middle, & Lower Left / Pete Johnson - Left Center - W. Va. and Regional History Collections at WVU - Upper Right / Pete Johnson - Middle Right / Pete Johnson - Lower Right / W. Va, and Regional History Collections at WVU.

Layouts and text by David A. Vago Historic Resource Planning & Design

Erected 2023 by Tucker Culture, The West Virginia Humanities Council, Friends of Blackwater and Davis West Virginia.

Topics. This historical marker is listed in this topic list: Industry & Commerce. A significant historical year for this entry is 1886.

Location. 39° 7.698′ N, 79° 27.85′ W. Marker is in Davis, West Virginia, in Tucker County. Marker is on Appalachian Highway (West Virginia Route 32) south of William Avenue, on the right when traveling south. Marker is located in the Town of Davis Riverfront Park. Touch for map. Marker is in this post office area: Davis WV 26260, United States of America. Touch for directions.

Other nearby markers. At least 8 other markers are within walking distance of this marker. From Forest To Sawmill (here, next to this marker); A Growing And Evolving Industry On The Riverbanks (a few steps from this marker); A Prosperous Sawmill Town (a few steps from this marker); Shipping By Rail (a few steps from this marker); Myrtle Mae (Hockman) Shrader (within shouting distance of this marker); Verzi's Saloon (about 300 feet away, measured in a direct line); The Pennsylvania House (about 300 feet away); The Blackwater Hotel (about 300 feet away). Touch for a list and map of all markers in Davis.

Credits. This page was last revised on December 10, 2023. It was originally submitted on December 4, 2023, by Bradley Owen of Morgantown, West Virginia. This page has been viewed 40 times since then and 12 times this year. Photos: 1, 2. submitted on December 10, 2023, by Bradley Owen of Morgantown, West Virginia.