Tahawus in Essex County, New York — The American Northeast (Mid-Atlantic)

Making Iron

EVOLUTION OF THE FURNACE

The "new” furnace, south of the village, was the culmination of 30 years of experimentation aimed at producing high quality iron efficiently. European experts were consulted, and metallurgists were hired to refine the process to make the best iron. The approach was part science and part craft, implemented by backbreaking and blistering labor.

IRON MAKING FORMULA

Iron Ore - Iron oxide, along with other trace elements considered impurities. A very pure iron oxide ore was found here, easily accessible and close to the surface.

BLOOMERY FORGE

The earliest type of forge produced a crude form of iron that required further processing to remove impurities.

- Iron and charcoal added through the top

- Air from bellows

- "Bloom", a molten mass of iron and slag

- Slag [tapped off the top of the bloom]

CUPOLA FURNACE

A simple furnace that used cold blast air. The stack from a cupola furnace lies alongside the ruins of the 1844 blast furnace.

- Iron ore, charcoal, and flux added through the top

- Round steel stack, lined with firebrick

- Blast air from a bellows

- Molten iron and slag [tapped from the bottom]

HOT BLAST FURNACE

The most sophisticated furnaces built here were hot blast furnaces, one built in 1844, and the "new” furnace built in 1854. These furnaces used water powered air cylinders to blast pre-heated air into the furnace. - A major improvement in efficiency came when the design was changed to preheat the blast air using hot gases from the chimneys

- Charcoal, iron ore, and flux were added in alternating layers

- The furnace could be tapped twice a day, yielding about six tons of iron each time

Topics. This historical marker is listed in this topic list: Industry & Commerce. A significant historical year for this entry is 1844.

Location. 44° 5.336′ N, 74° 3.354′ W.

Photographed By Steve Stoessel, March 28, 2020

2. Right Inset

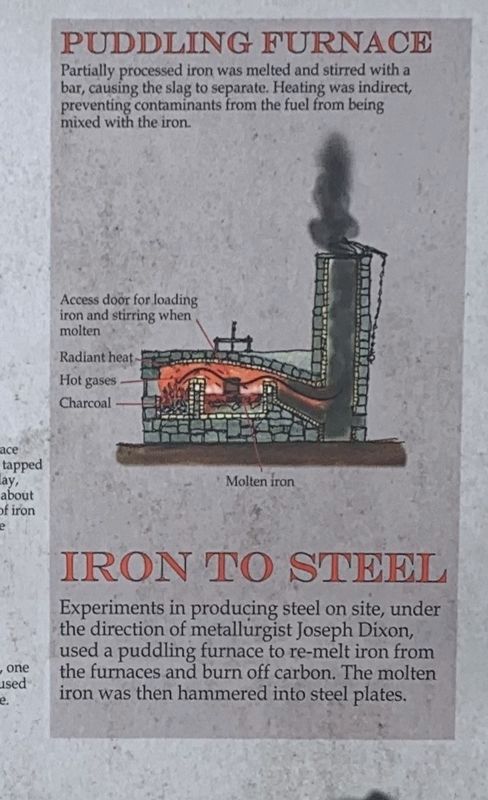

IRON TO STEEL

Experiments in producing steel on site, under the direction of metallurgist Joseph Dixon, used a puddling furnace to re-melt iron from the furnaces and burn off carbon. The molten iron was then hammered into steel plates.

PUDDLING FURNACE

Partially processed iron was melted and stirred with a bar, causing the slag to separate. Heating was indirect, preventing contaminants from the fuel from being mixed with the iron.

Experiments in producing steel on site, under the direction of metallurgist Joseph Dixon, used a puddling furnace to re-melt iron from the furnaces and burn off carbon. The molten iron was then hammered into steel plates.

PUDDLING FURNACE

Partially processed iron was melted and stirred with a bar, causing the slag to separate. Heating was indirect, preventing contaminants from the fuel from being mixed with the iron.

Other nearby markers. At least 8 other markers are within walking distance of this marker. David Henderson (a few steps from this marker); Coe Cottage (within shouting distance of this marker); The Money Men (about 300 feet away, measured in a direct line); From Rock to Iron (about 300 feet away); Transportation (about 400 feet away); Jennings Cottage (about 400 feet away); W.R.K. Taylor Jr. (about 400 feet away); Lazy Lodge (about 500 feet away). Touch for a list and map of all markers in Tahawus.

Photographed By Steve Stoessel, March 28, 2020

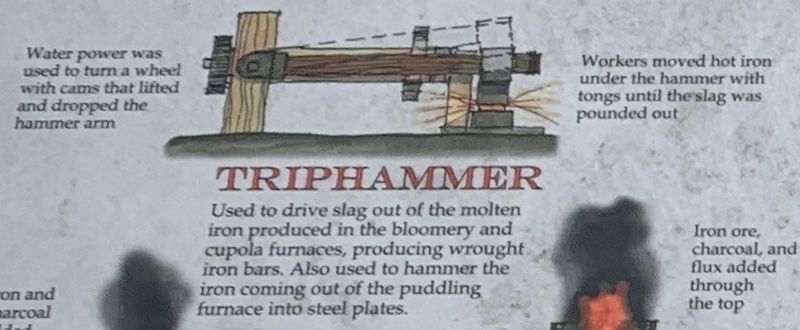

3. Triphammer Inset

Used to drive slag out of the molten iron produced in the bloomery and

cupola furnaces, producing wrought. iron bars. Also used to hammer the

iron coming out of the puddling furnace into steel plates.

- Water power was used to turn a wheel with cams that lifted and dropped the hammer arm

- Workers moved hot iron under the hammer with tongs until the slag was pounded out

- Water power was used to turn a wheel with cams that lifted and dropped the hammer arm

- Workers moved hot iron under the hammer with tongs until the slag was pounded out

Credits. This page was last revised on April 15, 2020. It was originally submitted on April 13, 2020, by Steve Stoessel of Niskayuna, New York. This page has been viewed 130 times since then and 6 times this year. Photos: 1. submitted on April 13, 2020, by Steve Stoessel of Niskayuna, New York. 2, 3. submitted on April 14, 2020, by Steve Stoessel of Niskayuna, New York. • Michael Herrick was the editor who published this page.

Editor’s want-list for this marker. A wide angle photo of the marker and its surroundings. • Can you help?