Near Snow Hill in Worcester County, Maryland — The American Northeast (Mid-Atlantic)

Nassawango Iron Furnace

circa 1828 - 1850

— National Historic Mechanical Engineering Landmark —

Inscription.

Nassawango is structurally typical of its period while distinctive in several ways: it smelted bog ore; it is principally of brick rather than stone; and of greatest significance, it probably is the earliest surviving American furnace that employed the “hot blast.” By this means--now universally used--the production of pig iron was greatly increased. The cast-iron blast-air “stove” at the top of the furnace stack was installed here ca. 1835, less than a decade after introduction of the process, in England.

Erected 1991 by The American Society of Mechanical Engineers.

Topics and series. This historical marker is listed in this topic list: Industry & Commerce. In addition, it is included in the Historic Mechanical Engineering Landmarks series list. A significant historical year for this entry is 1835.

Location. 38° 12.233′ N, 75° 28.15′ W. Marker is near Snow Hill, Maryland, in Worcester County. Marker can be reached from the intersection of Old Furnace Road and Millville Road. Located within the Furnace-Town Living History Museum. Entrance fees apply. Closed during off-season. Touch for map. Marker is at or near this postal address: 3816 Old Furnace Road, Snow Hill MD 21863, United States of America. Touch for directions.

Other nearby markers. At least 8 other markers are within 5 miles of this marker, measured as the crow flies. A different marker also named Nassawango Iron Furnace (approx. 1.1 miles away); Askiminokonson (approx. 3˝ miles away); Historic Western Auto Building (approx. 4˝ miles away); Makemie Memorial Presbyterian Church (approx. 4˝ miles away); Worcester County Courthouse (approx. 4˝ miles away); World War I Memorial (approx. 4˝ miles away); World War II Memorial (approx. 4˝ miles away); Snow Hill Town (approx. 4˝ miles away). Touch for a list and map of all markers in Snow Hill.

More about this marker. Located at the top of the iron furnace

Also see . . . Furnace Town Living Heritage Museum. (Submitted on May 23, 2011, by Bernard Fisher of Richmond, Virginia.)

Photographed By Nate Davidson, August 2, 2010

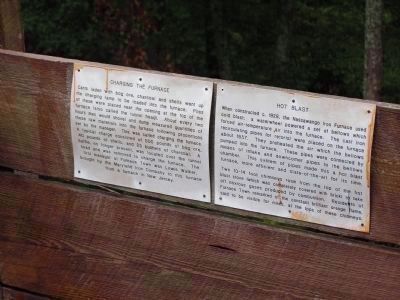

4. Charging the Furnace & Hot Blast

Two 10-14 foot chimneys rose from the top of the hot blast stove (which was completely covered with brick) to take off noxious gases produced by combustion. Residents of Furnace Town remarked of the constant brilliant orange flame, said to be visible for miles, at the tops of these chimneys.

Photographed By Nate Davidson, August 2, 2010

5. Mill Race & Overview

Below is the depression remaining from the mill race. In the 1840's water from a 300 acre pond (now woodland) flowed through a gate in the dam (now Old Furnace Road) into the mill race. This water provided power for the water wheel.

From this position ironworkers could easily view the warehouses, the Ironmaster's Mansion, and the various town buildings. Some 5000 acres of trees had been cut for the furnace project: to make room for the 25-acre town area: to supply wood for lumber for the town, and to make the charcoal needed to fuel the furnace.

From this position ironworkers could easily view the warehouses, the Ironmaster's Mansion, and the various town buildings. Some 5000 acres of trees had been cut for the furnace project: to make room for the 25-acre town area: to supply wood for lumber for the town, and to make the charcoal needed to fuel the furnace.

Credits. This page was last revised on March 13, 2023. It was originally submitted on May 22, 2011, by Nathan Davidson of Salisbury, Maryland. This page has been viewed 640 times since then and 16 times this year. Photos: 1, 2, 3, 4, 5, 6. submitted on May 22, 2011, by Nathan Davidson of Salisbury, Maryland. • Bernard Fisher was the editor who published this page.