Near Thurmont in Frederick County, Maryland — The American Northeast (Mid-Atlantic)

Dirty and Dangerous

Catoctin Furnace African American Cemetery Interpretive Trail

— No. 2 —

“The bones of Catoctin men and women show —almost literally— the effects of back-breaking labor. One elderly man's spine was so damaged by a lifetime of hard work that he was unable to stand up straight. Furnace labor and exposure to hazardous fumes also threatened the health of pregnant women, infants, and children. Most women died during their child-bearing years, and infants and children are well-represented in the Catoctin cemetery.”

— Karin Bruwelheide, Smithsonian, Museum Specialist and Skeletal Biologist, 2020

Making iron and forging metal was dirty and dangerous work. Backbreaking labor, burns, and fume fever (caused by inhalation of airborne toxins) were commonplace. Death sometimes occurred by falling into the stack or getting caught in machinery, such as the water wheel.

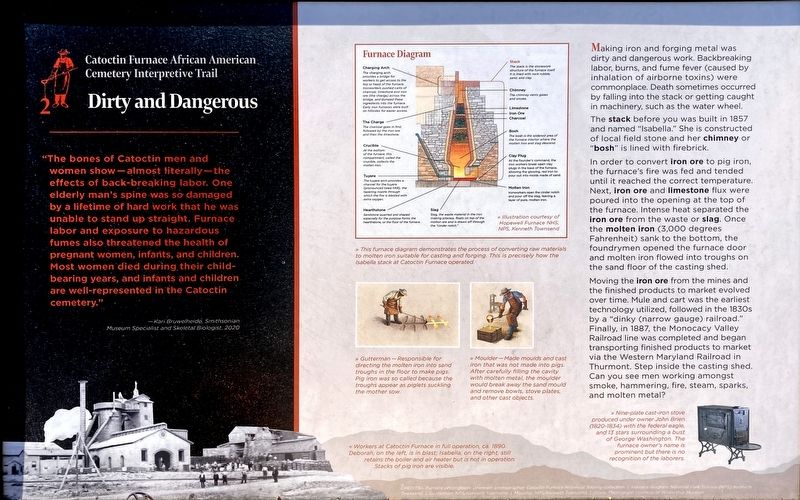

The stack before you was built in 1857 and named “Isabella.” She is constructed of local field stone and her chimney or “bosh” is lined with firebrick.

In order to convert iron ore to pig iron, the furnace's fire was fed and tended until it reached the correct temperature. Next, iron ore and limestone flux were poured into the opening at the top of the furnace. Intense heat separated the iron ore from the waste or slag. Once the molten iron (3,000 degrees Fahrenheit) sank to the bottom, the foundrymen opened the furnace door and molten iron flowed into troughs on the sand floor of the casting shed.

Moving the iron ore from the mines and the finished products to market evolved over time. Mule and cart was the earliest technology utilized, followed in the 1830s by a “dinky (narrow gauge) railroad.” Finally, in 1887, the Monocacy Valley Railroad line was completed and began transporting finished products to market via the Western Maryland Railroad in Thurmont. Step inside the casting shed. Can you see men working amongst smoke, hammering, fire, steam, sparks, and molten metal?

Erected by Maryland Historical Trust; Maryland Commission on African American History and Culture; Maryland Park Service, Maryland Department of Natural Resources. (Marker Number 2.)

Topics and series. This historical marker is listed in these topic lists: African Americans • Cemeteries & Burial Sites • Industry & Commerce. In addition, it is included in the Maryland Historical Trust series list. A significant historical year for this entry is 1857.

Location. 39° 34.869′ N, 77° 26.047′ W. Marker is near Thurmont, Maryland, in Frederick County. Marker can be reached from Catoctin Furnace Road (Maryland Route 806) 0.1 miles north of Catoctin Hollow Road, on the left when traveling north. Touch for map. Marker is at or near this postal address: 12698 Catoctin Furnace Rd, Thurmont MD 21788, United States of America. Touch for directions.

Other nearby markers. At least 8 other markers are within walking distance of this marker. Catoctin Furnace African American Cemetery Interpretive Trail (here, next to this marker); Catoctin Iron Furnace (here, next to this marker); a different marker also named Catoctin Iron Furnace (a few steps from this marker); The Watchful Eye (a few steps from this marker); Catoctin Furnace (a few steps from this marker); A Diverse and Skilled Workforce (a few steps from this marker); Ironmaster's Mansion (about 300 feet away, measured in a direct line); Ruins of the Ironmaster’s House (about 400 feet away). Touch for a list and map of all markers in Thurmont.

Photographed By Allen C. Browne, October 18, 2021

3. Furnace Diagram

» This furnace diagram demonstrates the process of converting raw materials

to molten iron suitable for casting and forging. This is precisely how the

Isabella stack at Catoctin Furnace operated. Diagram by National Park Service/Kenneth TownsendClose-up of image on marker.

Library of Congress

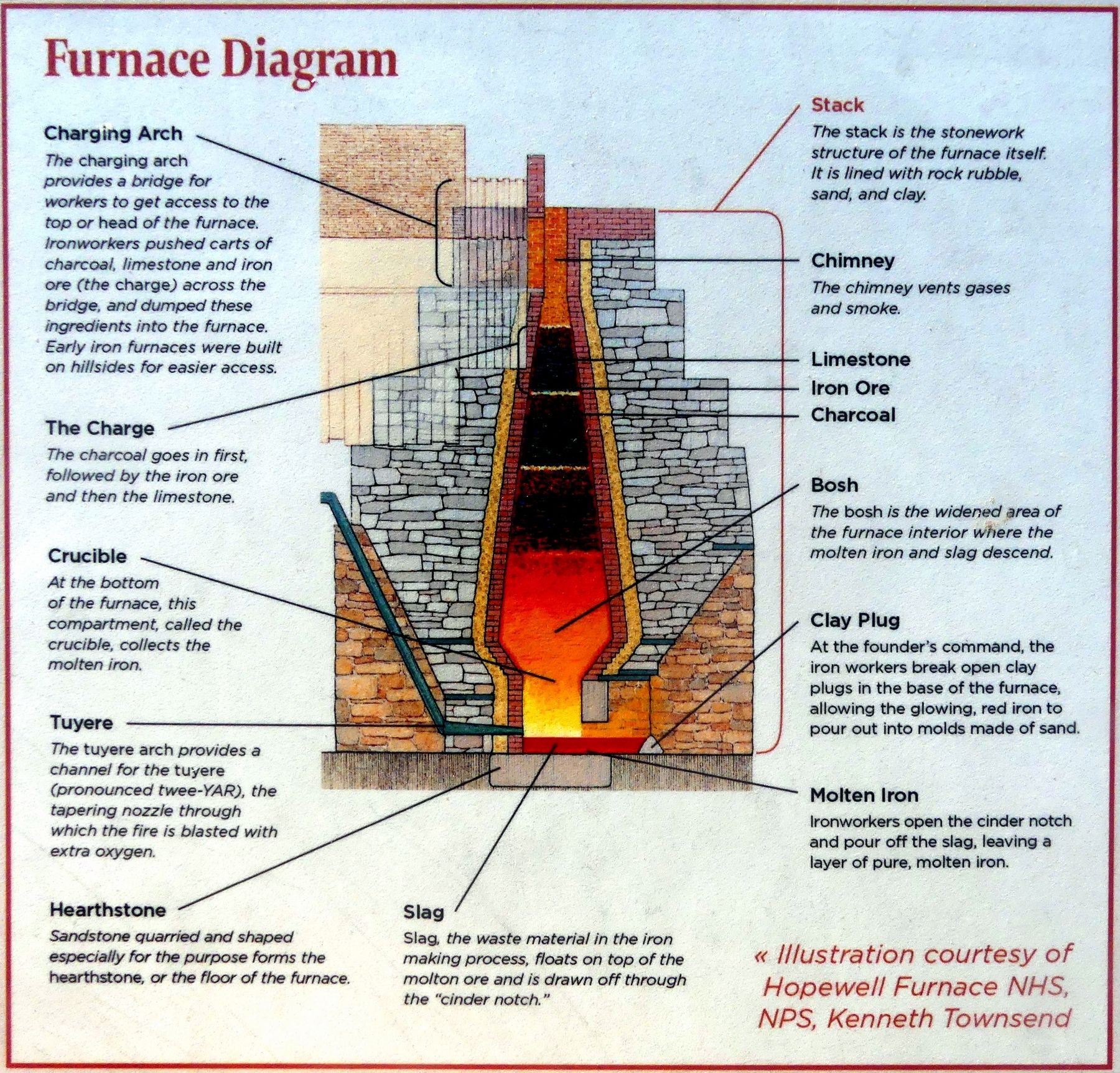

5. Moulder

» Moulder — Made moulds and cast iron that was not made into pigs. After carefully filling the cavity with molten metal, the moulder would break away the sand mould and remove bowls, stove plates, and other cast objects. From a map by The National Park Service/Kenneth Townsend.

Photographed By Allen C. Browne, October 18, 2021

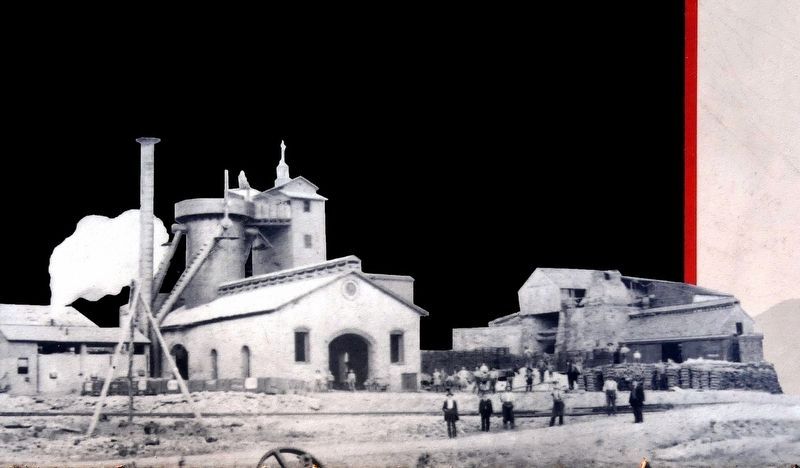

6. Workers at Catoctin Furnace in Full Operation

« Workers at Catoctin Furnace in full operation, ca. 7890. Deborah is in blast; Isabella, on the right, still retains the boiler and air heater but is not in operation. Stacks of pig iron are visible. Photograph by unknown photographer. Catoctin Furnace Historical Society Collection.Close-up of photo on marker.

Credits. This page was last revised on October 23, 2021. It was originally submitted on October 19, 2021, by Allen C. Browne of Silver Spring, Maryland. This page has been viewed 163 times since then and 12 times this year. Last updated on October 21, 2021, by Allen C. Browne of Silver Spring, Maryland. Photos: 1, 2, 3, 4, 5, 6. submitted on October 19, 2021, by Allen C. Browne of Silver Spring, Maryland. • J. Makali Bruton was the editor who published this page.