Birmingham in Jefferson County, Alabama — The American South (East South Central)

The Gas System

Sloss Furnaces National Historic Landmark

The Gas System

Gas produced in the furnace as a by-product of the ironmaking process was used in the plant as fuel. A large pipe called the downcomer carried gas from the top of the furnace to the gas cleaning equipment, which removed the dirt and dust. Once cleaned, the gas was piped throughout the plant. The stoves burned part of the gas to pre-heat the air blast. The boilers burned the remainder to produce the steam that powered much of the plant's machinery.

The Process

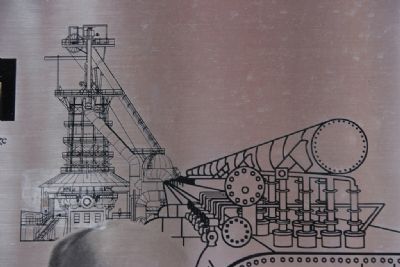

The blast furnace produced an enormous quantity of gas. A 450-ton furnace such as this one produced up to 80 million cubic feet of gas per day. The gas contained about 15 percent carbon dioxide, 24 percent carbon monoxide, 4 percent hydrogen, and 57 percent nitrogen. Suspended in the gas were about 12 tons of flue dust that had to be removed before the gas could be used.

That the furnace gave off a usable gas was just fortunate circumstance. When the hot blast of air entered the furnace through the tuyeres, its oxygen reacted with the coke. The resulting gases swept up through the raw materials, and after a series of chemical reactions left the furnace as heated, dust-laden, combustible gas. This current of gas reached its peak velocity-about 450 feet per second (306 mph)- near the top of the furnace. The gas flowed out through the brick-lined downcomer and into the dustcatcher. The dustcatcher was designed to reduce the velocity of the gas so the large particles of dust would settle to the bottom where they could be drawn off at regular intervals. With the large particles removed, the gas passed to the horizontal washer. There it was sprayed with water to wash out the fine particles of dust. The gas was then ready to use, although it was not completely dust free. Normal blast furnace gas had enough combustible carbon monoxide to have a heating value of 85 to 100 Btu per cubic foot. This represented about 45 percent of the calorific power of the coke charged into the furnace.

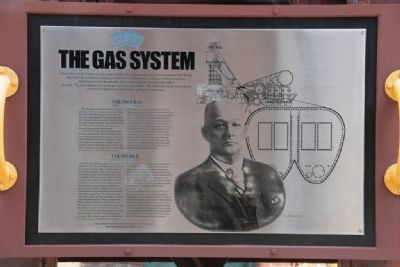

The People

James Pickering Dovel, author and inventor, spent most of his life searching for ways to improve blast furnace operation. Born in 1868 in the community of Pickerington, Ohio near Columbus, Dovel spent his early years running a farm for his invalid father. Still, his inventive genius did not go untapped. The hard work of farming turned his attention to the need for labor saving machinery and stirred him, at age seventeen, to invent a mechanical corn harvester. While the device was never patented, it was adopted by several manufacturers of farm equipment. The depression of the 1890s drove Dovel, his wife and children to the city, where he landed a job at Columbus Steam and Boiler Company. Within days Dovel's boss had discovered his talent and promoted him to foreman, launching a long career in industrial invention.

In 1905 Dovel moved to Birmingham to become superintendent of the Birmingham Engineering Company. While there he supervised construction of a blast furnace for Woodward Iron Company. Four years later he joined Sloss as superintendent of construction. For the next twenty-one years, Sloss was Dovel's workshop for invention. He developed gas cleaning equipment, modified the design of the furnaces, and improved the linings of the furnaces. In all, some seventeen patents are credited to Dovel. Sloss's No. 2 Furnace, rebuilt in 1927, included many of these inventions, earning Dovel and Sloss a national reputation for innovation. Arthritis confined Dovel to bed in 1933, but it did not end his career. In 1940 he received the Modern Pioneer Award from the National Association of Manufacturers in honor of his "distinguished achievement in the field of science and invention." During World War II, Dovel worked by telephone from his hospital bed, advising blast furnace operators around the country in the use of his many patented innovations. At the time of his death, more than fifty furnaces were using his inventions.

Special thanks to the family of James Pickering Dovel for their assistance with the preparation of this interpretive sign.

Erected by Sloss Furnaces Historic Landmark.

Topics and series. This historical marker is listed in this topic list: Industry & Commerce. In addition, it is included in the National Historic Landmarks series list. A significant historical year for this entry is 1868.

Location. 33° 31.237′ N, 86° 47.468′ W. Marker is in Birmingham, Alabama, in Jefferson County. Marker can be reached from 32nd Street North. Marker is located between the water tower and Furnace No. 1 on the grounds of Sloss Furnaces National Historic Landmark. Touch for map. Marker is at or near this postal address: Twenty 32nd Street North, Birmingham AL 35222, United States of America. Touch for directions.

Other nearby markers. At least 8 other markers are within walking distance of this marker. Slag (a few steps from this marker); Boilers (within shouting distance of this marker); The Blast Furnace (within shouting distance of this marker); Ironmaking (within shouting distance of this marker); Casting Pigs (within shouting distance of this marker); The Stock Trestle (within shouting distance of this marker); Stock Trestle/Tunnel (within shouting distance of this marker); The Blowing Engine Room (within shouting distance of this marker). Touch for a list and map of all markers in Birmingham.

Also see . . . Sloss Furnaces National Historic Landmark website. (Submitted on June 24, 2011, by Timothy Carr of Birmingham, Alabama.)

Credits. This page was last revised on June 16, 2016. It was originally submitted on June 22, 2011, by Timothy Carr of Birmingham, Alabama. This page has been viewed 895 times since then and 18 times this year. Photos: 1, 2, 3, 4, 5, 6, 7, 8, 9, 10. submitted on June 22, 2011, by Timothy Carr of Birmingham, Alabama. • Bill Pfingsten was the editor who published this page.